#3DExpress: SpaceX to Collaborate With Velo3D?

This week, we take you on a little trip into space with SpaceX: the company has reportedly signed a licensing and support agreement with metal 3D printer manufacturer Velo3D. This is good news for Velo3D, which had been struggling for several months. Meanwhile, Steakholder Foods has opened a demonstrator center fo food 3D printing and there have been encouraging developments in construction 3D printing in France. Last but not least, we tell you about the WorldSkills 2024 results and the partnership between Toolcraft and Siemenes. Read on to find out more!

SpaceX Enters Into Deal with Velo3D

Velo3D is back in the news! After hearing last week about the company’s delisting on the NYSE, some positive news has come to the metal 3D printer manufacturer. It seems that earlier this week, Velo3D entered into a licensing and support agreement with SpaceX in an $8 million deal, in a move that many in the industry are heralding as “lifesaving” for the struggling AM solutions provider. Whether this is the case remains to be seen, but the deal itself encompasses a fee of $5 million for the technology license, as well as a further $3 million for engineering and support services. The license is worldwide, non-exclusive, royalty-free and perpetual, meaning that SpaceX will be able to manufacture, modify and develop Velo3D’s technology for internal operations. Furthermore, this also covers any improvements or modifications made to the technology by Velo3D in the next 12 months. After that period, changes made by Velo3D will remain the company’s sole property, while those made by SpaceX will remain under their own IP. Hopefully the deal will not only help Velo3D to continue to advance but also be a huge milestone in the use of additive manufacturing in the space industry.

Photo Credits: SpaceX

Steakholder Foods Opens a Demonstration Center for Food 3D printing

Israeli food technology company Steakholder Foods this week announced the opening of a new demonstration center. Interested parties will be able to get an on-the-spot idea of how plant-based food production is achieved using 3D printing. The showpieces of food production – the MX200 and HD144 printing plants – will of course be part of the demonstration center, printing live for visitors. The aim of Steakholder Foods is, on the one hand, to raise awareness and illustrate alternative food production and, on the other, to strengthen customer loyalty and attract new customers. Arik Kaufman, CEO of Steakholder Foods, commented: “We believe that our demonstration center will be a cornerstone of interaction with potential customers and partners. It’s not just about seeing the technology in action – it’s about experiencing the future of food production in real time. This center will play a crucial role in promoting our capabilities and building stronger relationships within the industry.”

Photo Credits: Itamar Ginsburg

Encouraging Certification for Plurial Novilia Project

You may have heard of Plurial Novilia’s latest construction project, ViliaSprint². This is a building of 12 multifamily dwellings whose walls will be 3D printed in Champagne-Ardenne. And the reason we’re talking to you about it again today is that the project has just been awarded the ATEx by the CSTB, a technical assessment that “evaluates innovative products or processes not covered by a technical opinion, thus facilitating innovation in the construction sector.” In concrete terms, this will enable the project to move into the operational phase. As a reminder, the building is 3 storeys high, and prototypes of 3-metre-high by 4-metre-wide walls have been tested for many months – fire resistance, structural and mechanical tests. The printing phase is due to start at the end of the year, and the work will take 18 months to complete.

3D-printed wall prototypes (photo credits: Plurial Novilia)

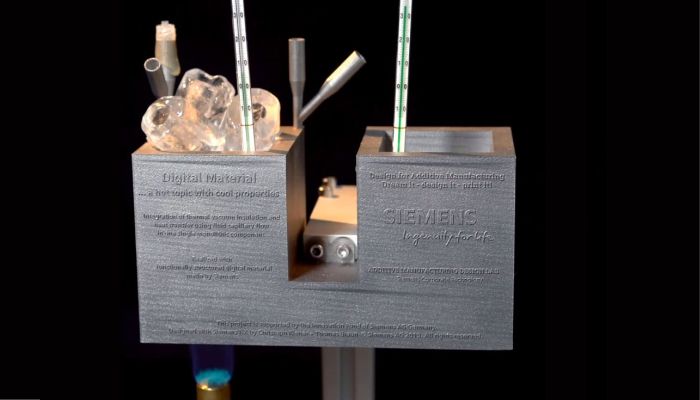

Toolcraft and Siemens Print Porous Metal Structures for Industrial Applications

Toolcraft and Siemens Digital Industries have joined forces to advance the industrial applications of porous metal structures. The 3D-printed structures are to be optimized to meet structural and functional requirements in industry. This is difficult to achieve with conventional processes. However, as the pore size can be precisely controlled with powder bed fusion, the two partners have opted for this process. “We see potential applications primarily in the process industry, energy process engineering and aerospace. However, applications in mechanical engineering and medical technology are also conceivable. With Toolcraft, we have a long-standing partner at our side who builds the strategic bridge to the industrial production of these sophisticated material structures. We are delighted that Toolcraft can take on this role,” explains Dr. Karsten Heuser, VP Additive Manufacturing at Siemens Digital Industries.

Bild: toolcraft

Who Won Worldskills 2024 in the Additive Manufacturing Category?

Let’s close this edition of #3DExpress with a message about the young 3D printing generation. As you may know, the grand finale of the International Skills Competition took place last week. Thousands of young people under the age of 23 competed to represent their country and showcase their skills in various categories. Among them was additive manufacturing. Victory in the “Additive Manufacturing” category went to Korea, followed by France in 2nd place and China in 3rd place. In any case, it seems that the future is bright with these youths at the helm.

The winners in additive manufacturing

What do you think of the deal between Velo3D and SpaceX? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.